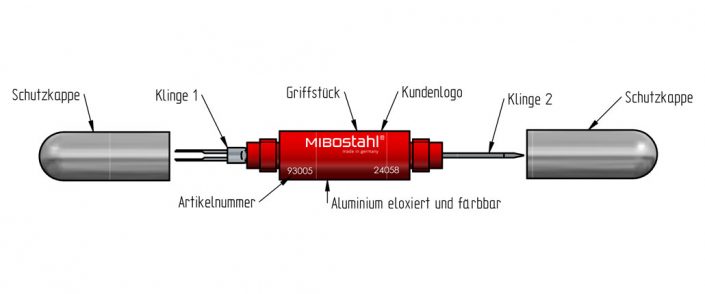

Terminal extraction tools for any plug connection and any secondary locking mechanism

When working on wiring systems, it is of critical importance to use the proper know-how and right tools to guarantee correctly functioning, fault-free connections as quickly as possible. The use of state-of-the-art production methods, premium quality components and precise tools are key factors here.